PTFE

PolyTetraFluorEthylen (PTFE) has unique properties. The molecular structure and the high bond energy between the Fluor and Carbon atoms result in nearly universal resistance to chemicals and solvents. Due to its high temperature resistance, good slide and non-stick properties, PTFE has a wide field of applications.

PDF Info PTFEPTFE Films

PTFE films are mainly produced via a special peeling of cylindrical blocks (skived films). These blocks are produced under high pressure and temperatures from virginal or compounded PTFE powder.

Dip Coating

Dip Coating

The standard coating of fabrics is the dip coating process. The fabric is pulled through a PTFE dispersion. In a second step the PTFE is fused on a vertical oven at 380 °C. Only heat resistant fabrics such as glass or aramid can be used. PTFE can only be coated in very thin layers; thus the dip coating process consists of several passes.

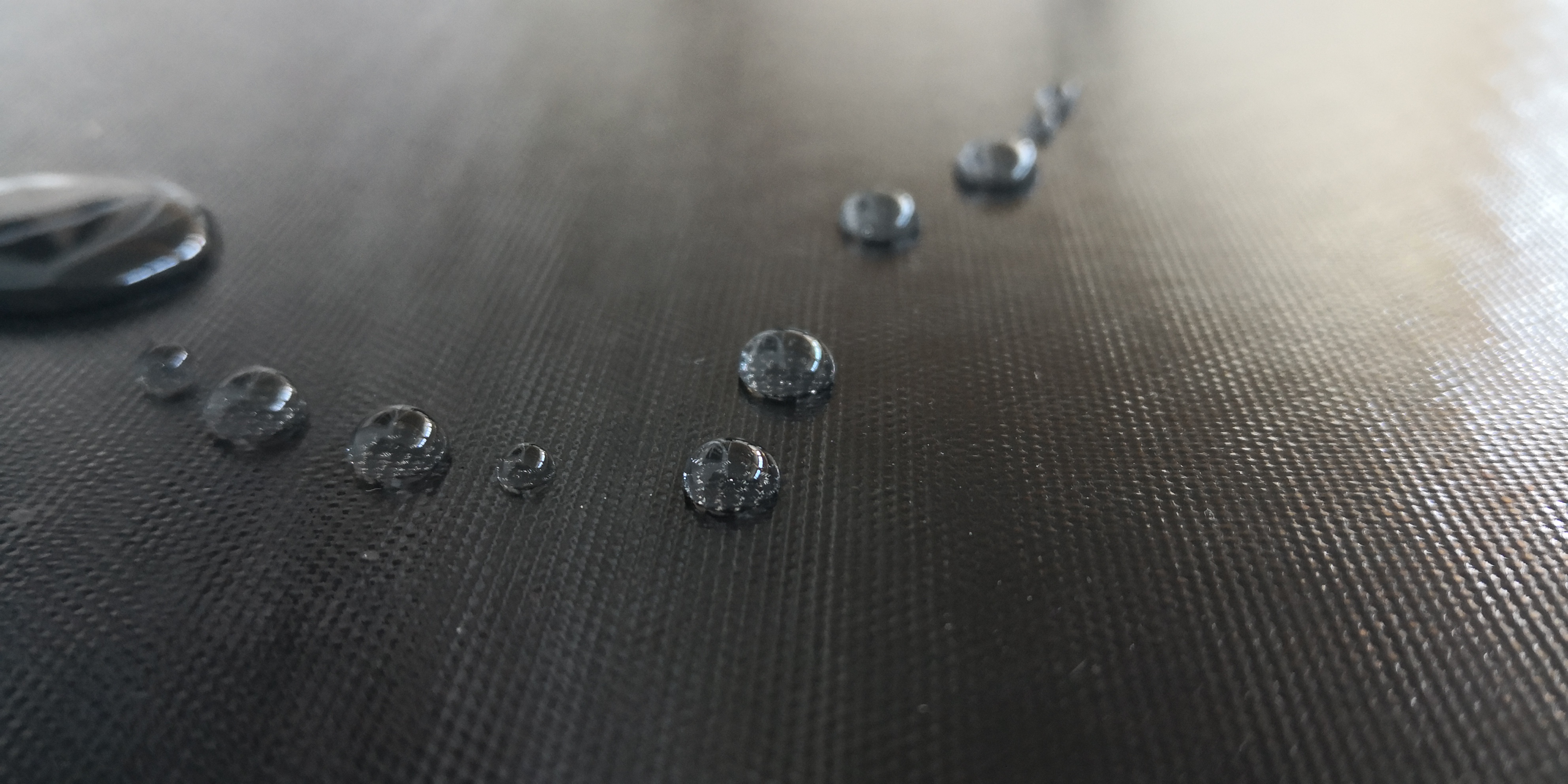

Lamination

Lamination

For high performance applications the surface of a dip coated PTFE glass fabric can be sealed with a meltable fluoropolymer film. Due to the low melt viscosity of the polymer film a homogeneous surface is obtained.

Contact Person

Philipp Kümmerle

Customer Support & Technology

This email address is being protected from spambots. You need JavaScript enabled to view it.

Dr. Matthias Grübel

Development

This email address is being protected from spambots. You need JavaScript enabled to view it.