Silicone

Silicone, cured polydimethylsiloxane (PDMS), is an inorganic polymer. In comparison to organic polymers based on a carbon backbone, silicone is based on silicon and oxygen.

Silicones are duroplastic elastomers, thus after curing they cannot be melt processed. Good non-stick properties, a high degradation temperature and a low glass transition temperature (-120 °C) result in a wide temperature application range (-80 °C up to 180 °C).

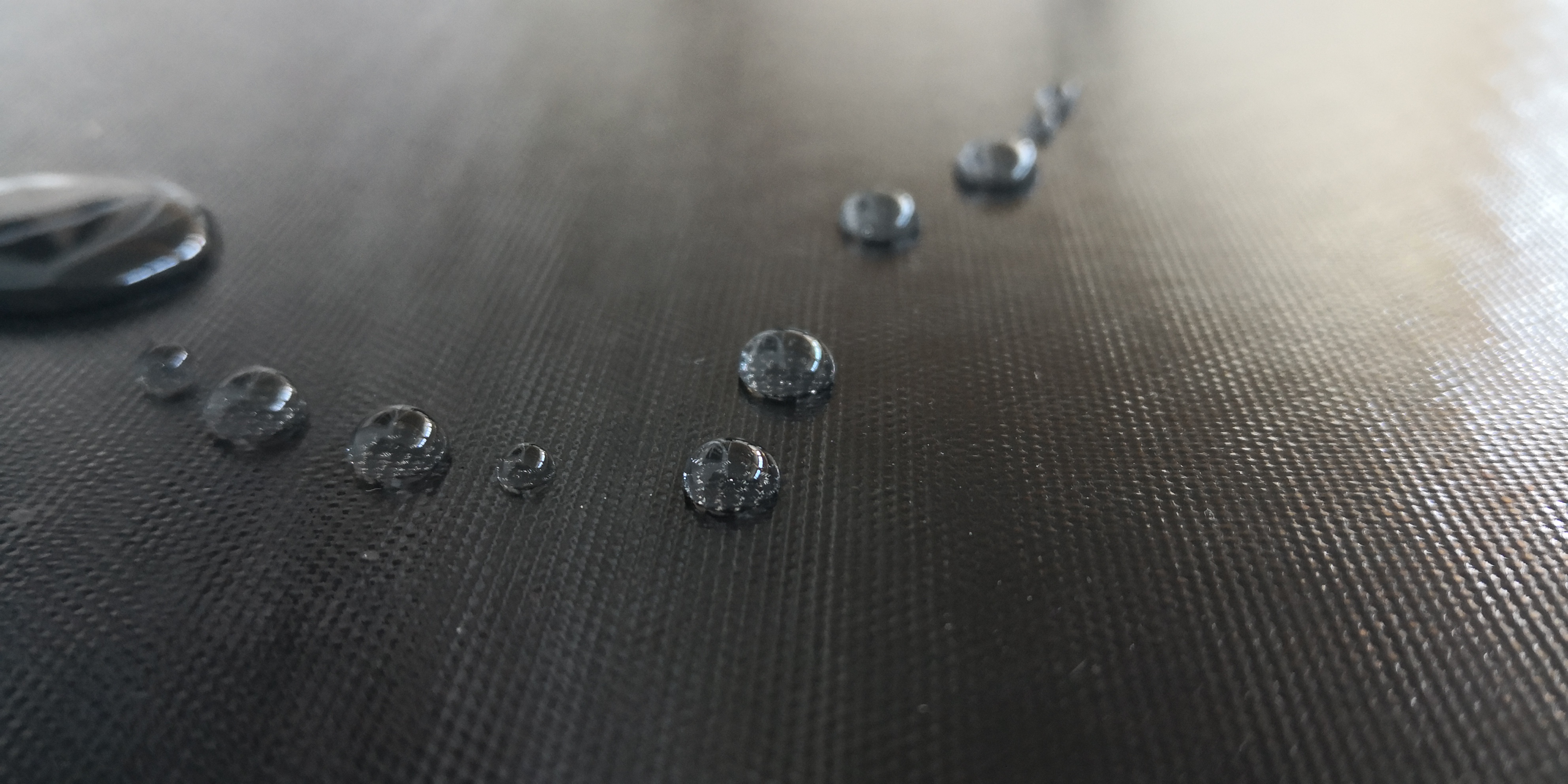

Silicone coated fabrics

knife coating process

Silicone coated fabrics are produced mainly via a knife coating process. The uncured high viscous silicone paste is applied on the fabric. A knife bar in a defined distance to the fabric determine the layer thickness of the silicone coating. In a consecutive oven the silicone is cured via a hydrosilylation addition reaction (Pt- catalysed).

The curing temperature is lower compared to PTFE. Therefore, a broad variety of fabrics can be used, such as glass, aramid, polyester, polyamide. Additives in the silicone can change the properties. The temperature stability is improved by Fe 3 O 4 .

Contact Person

Philipp Kümmerle

Customer Support & Technology

This email address is being protected from spambots. You need JavaScript enabled to view it.

Dr. Matthias Grübel

Development

This email address is being protected from spambots. You need JavaScript enabled to view it.